Сontract manufacturing and electronics supply

Сontract manufacturing and electronics supply – the main activity of the company CATU Tech.

More than 10 years, we have been providing a full range of services for the electronics contract manufacturing – from the PCB production, mounting, testing and assembly to the creation of turnkey solutions.

High-tech manufacturing, professionalism of employees and extensive experience in implementing projects of any complexity allow us to offer optimal solutions taking into account all the features of each project, as well as clear and high-quality execution in accordance with the requirements of our customers.

We also provide technical and service support for your production and constantly replenish our warehouse of spare parts

ADVANTAGES

The whole range of necessary PCBs and assembly products

High-tech equipment and production facilities

Electronic components mounting of any form factor and complexity

Quality control at all stages

Main Features

Affordable prices

Savings allows you to get a low cost of the device without losing its functionality. This is achieved due to the careful selection of material for the PCB manufacture, the price of which differs significantly in piece, small-scale and mass production.

The shortest production time

Production time directly depends on the requirements of customer. Technology and equipment for urgent orders are selected in such a way that the manufacturing process takes a minimum time.

Quality assurance

PCBs quality is determined by the quality of the material and well-conducted production process, using high-tech equipment.

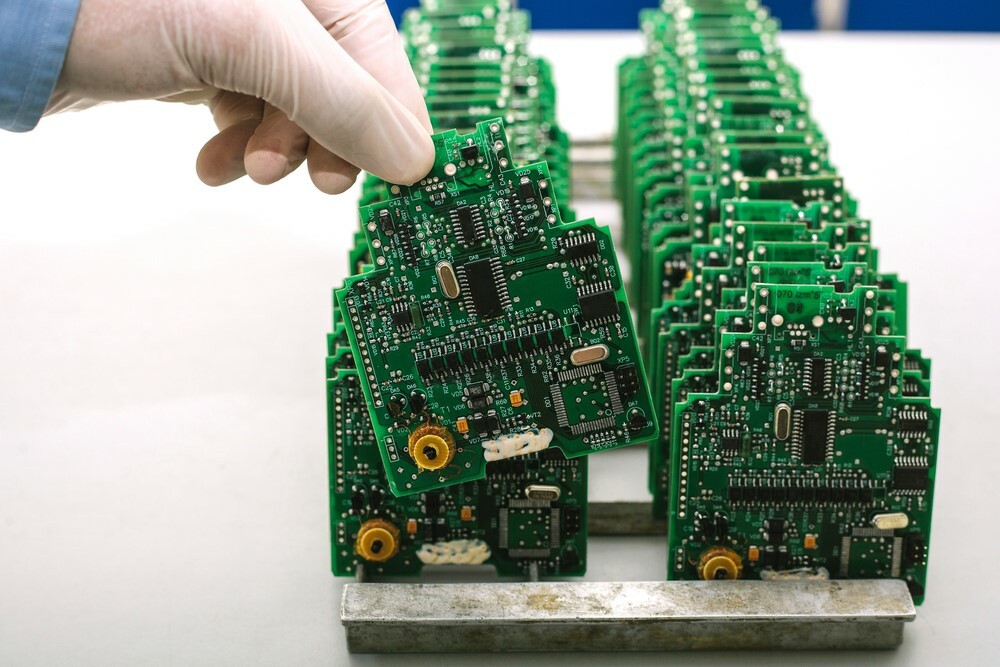

Features of the production line

Modern high-performance equipment and a team of experienced professionals guarantee favorable conditions in terms of price-quality ratio. Each PCB is tested by the Quality Control Department and is accompanied by a guarantee. To achieve excellent assembly quality and the most accurate solder paste application, we use automatic screen printer DESEN HITO Plus, that built into the surface mount line. SMD component mounting is carried out by flexible, high-speed, multifunctional pick&place machines from the recognized market leader Hanwha Precision Machinery. PCB soldering is carried out using the convection oven E-therm E8, which is in demand for medium and large-scale production.

High-precision SIEMENS PLC+PID temperature control and long heating zones for high production efficiency.In line also uses:

In line also uses:

- Inspection conveyors CYX 460XL, that will become reliable links in the technological process.

- PCB loader LDB 460XL with PCB dimensions 50×50-460×530 mm and thickness 0.6 – 4.5 mm;

PCB unloader ULDB 460XL with the ability to work with 3 magazines, conveyor speed 16 m/min and average unloading speed of 6 sec.

Order application

Application for the PCB production must contain:

- Finished project files in Altium, Gerber, P-CADxx formats.

- Files sent by e-mail must be compressed beforehand (ZIP or RAR archive).

- An accompanying project description containing additional information that will allow to correctly and quickly prepare PCB for starting production.

- Your contact details (full name, phone number, e-mail) for communication on organizational and technical issues.

Rеquest a call back

Address: Republic of Kazakhstan, Astana, Almaty district, Beyimbet Mailin street, house 23, n.p. 16, Postal code 010000

e-mail: info@catutech.kz